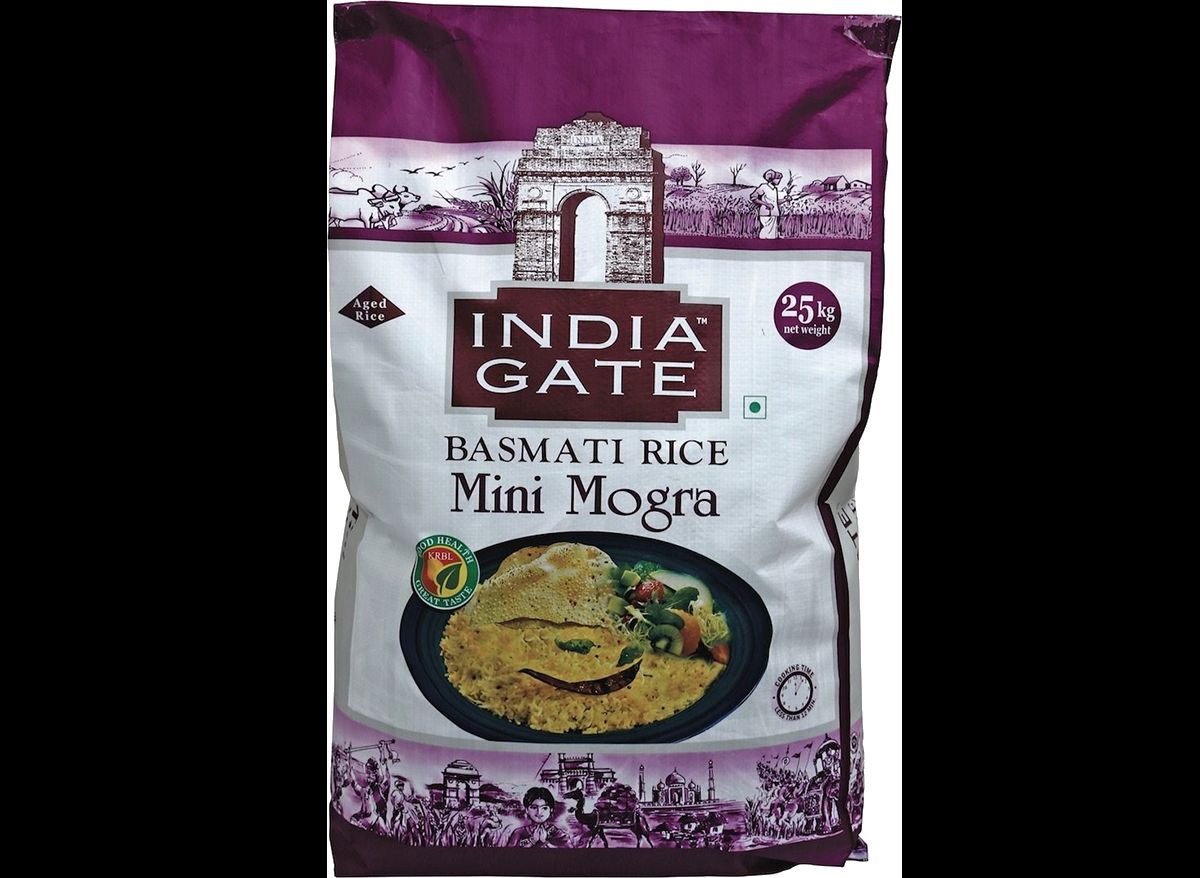

BOPP Printed Bags

BOPP (Biaxially Oriented Polypropylene) is a polypropylene film that is “Biaxially Oriented.”

This means the film is stretched in both the machine direction (MD) and across machine direction (AMD).

The result is packing with superior strength at low gauges, flatness, clarity, and excellent printability.

Let me go through a simple process, how we make a new bag as per your design.

- Make a Cylinder Die from Corel draw design file (CDR file) of your packing. Cylinder die will be costly. Here, Die costing increase by adding colors.

- From Die, we make two transparent films which will be applied over Plain PP Bag which prints PP Bag, provide extra protection from Direct UV light and adds glossy effect.

- We require to print minimum: 15000 Bags to provide in BOPP packing.

- Due to the complication of a process, it is not affordable for plastic industries to make just 5000 or 10000 Bags, we have to order it in a lot. It will take 1 month to complete from making a die to ready Bags.

Advantage :

- Clear Printing

- UV protected. Due to transparent film lamination, it adds protection.

- Highest strength

- The transparent film will laminate over PP Bag which results packing will be shiny.

- Water Resistance packing

Disadvantage :

- Costly packing due to cylinder die making is a very costly process. Although, printing charge is higher than rubber stereo printing.

- Bulk quantity required.

Types Printed PP Bags

- Uncoated Open Mouth Bags With/Without Hemming On Top

- Bags With PE Liner Sewn In Top And / Or Bottom

- Coated Bags – Available In A Variety Of Finishes

- Laminated Bags

- Bopp Bags

- Paper Coated Bags

- Aluminium Coated Bags

- Box Bags